- 6 min read

- Oct 18, 2024

- 0

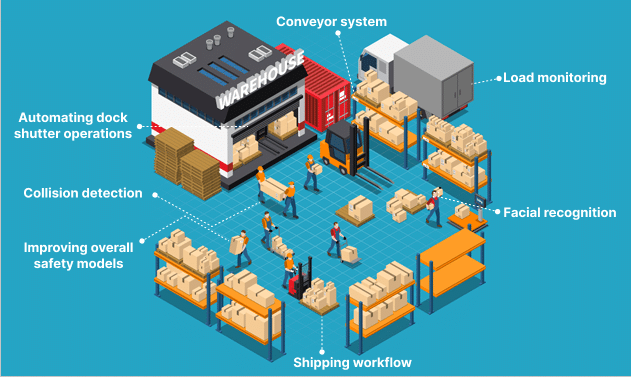

With the advancement of computer vision technology has led to an advanced era of warehouse management. Exploring the primordial hotspots for accidents within a warehouse ensures optimal warehouse safety protocols. Among these, conveyors, materials storage areas, and forklift zones stand out as the most critical aspects. Warehouses are considered the heart of the supply chain and with efficient approaches, it can streamline the distribution and logistics across industries. Therefore, it comprises many manual processes that could lead to various technical glitches.

Revolutionizing warehousing with computer vision

Here lies the importance of computer vision in warehousing. Computer vision powered by AI and machine learning has contributed to the warehouse industry. According to the latest research, it can be noted that the warehouse automation market is estimated to rebound with a robust 19% compound annual growth rate from 2024 to 2027. Computer vision can be seamlessly integrated into warehouses as a boosting agent for efficiency and innovation across the logistics infrastructure. Considering the OSHA compliances, a loading dock is a risk-prone zone having a quarter of all accidents taking place in this location. Most of the reported accidents in loading docks involve individuals being crushed down by trailers and forklifts.

This blog post curates a proactive approach to computer vision AI and how warehouse docks can be transformed boosting efficiency and safety concerns.

What are the major areas of transformation?

Vision AI can be seamlessly integrated into warehouse operations to transform several major areas. Worker safety is one of the primary concerns across warehouse docks. Right from slips and falls to accidents, the challenges are truly diverse and require proactive measures for mitigating potential hazards. Let’s explore how computer vision technology can play a significant role in overcoming these challenges.

Significance of PPE

PPE compliance comprises safety goggles, hard hats, high-visibility vests and steel-toed boots. Protective wearables are highly important for warehouse workers to prevent injuries and major accidents. PPE compliance detection across manufacturing, construction and warehouse verticals is extremely crucial. Vision AI can significantly identify and count items ensuring that inventory levels are maintained properly preventing overall economic losses. It covers a wide range of use cases such as intrusion detection, face recognition, real-time monitoring of events, vehicle detection and many more.

Importance of computer vision in amplifying the effectiveness of the dock equipment

Here the context unveils the tangible benefits of harnessing computer vision and AI in warehousing.

Load monitoring & optimization

Safety monitoring systems powered by AI effectively evaluate weight, alignment of loads and distribution on conveyor systems. AI Video surveillance software prevents overloading and falling of goods and diminishes overall strain on tools.

Improving overall safety models

Safety concerns hover across warehouse operational infrastructure. From detecting unsafe behaviour to monitoring workers’ activity, AI-powered video surveillance systems provide real-time alerts on the detection of any kind of suspicious activities.

Automated threshold control for conveyor system

Advanced intelligence helps in automating the process of stopping conveyor belts while reaching the heights. Vision AI technology can be integrated with conveyor controls for streamlining operations, reducing the risk of overloading, damage and safety hazards.

Collision detection

Video data from IP cameras can be analyzed using computer vision systems. It can seamlessly detect collisions between jacks and forklifts and identify collisions ensuring warehouse safety.

Automating dock shutter operations

By installing cameras equipped with Vision AI capabilities, the efficiency of warehouse dock operations can be improved. The Computer Vision Solution for Warehouse Safety is capable of detecting approaching trucks and can automate the activation of the opening and closing of the dock shutters.

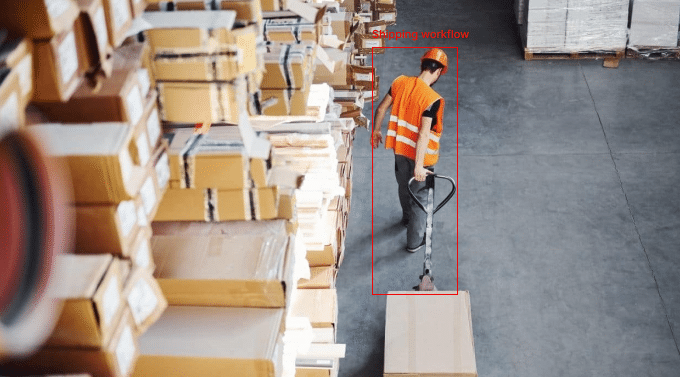

Optimizing the shipping workflow

Shipping is among the final processes in warehouse operations. The right products loaded in the right transport vehicles require operations without any glitches. Computer vision helps in the process of validating loading counts and recognizing pallets with precision. This helps in reducing shipping errors and contributing to a seamless supply chain flow. It potentially diminishes costly shipping workflow and enhances customer satisfaction.

Facial recognition

Deploying a face recognition system into the warehouse helps in enhancing security, identifying employees and having an automated attendance tracking system. Smart logistics uses advanced intelligence and big data to optimize the path of manufactured products from the factory warehouse to the end customer.

How computer vision improves performance at warehouse docks?

Computer vision is one of the best innovations in the branch of artificial intelligence. It assists in streamlining the operations involved in a warehouse dock.

Automatic number plate recognition

With the truck approaching the warehouse dock, an automatic number plate recognition system combined with vehicle detection systems integrates with IP cameras to capture the vehicle’s information. Using computer vision algorithms, the gathered video/image data can be extracted and analyzed accurately.

Arrival at the dock

With the arrival at the dock, the ANPR system signals the beginning of the monitoring process and cameras connected to the AI platform continuously monitor dock activities.

Dwell time analysis

The AI platform is empowered with the potential to analyze activity patterns in real time. It can look for signs of prolonged inactivity. Whenever a vehicle remains idle for an extended period(for a certain time-bound), the system flags this inconsistency as a potential issue.

Optimization & efficiency

Using computer vision algorithms the system can minimize dwell time and optimize dock operations. It increases the overall efficiency and productivity of warehouse dock operations.

Alerts & intervention

On real-time detection of activities, it sends prompt alerts to warehouse workers. This enables them to address issues such as reallocating resources, administering assistance to speed up warehouse operations and adjusting schedules.

Wrapping up

The warehousing industry is evolving at a rapid rate and embracing digital technologies for optimal business performance. It is adhering to best practices and strategically designing the layout, storage and operations to maximize delays and disruptions. By improving relevant areas of the warehouse workflow, and improving safety to unloading effectively, computer vision technology fosters an environment of continuous improvement. Nextbrain provides scalable and adaptable solutions catering to the diverse requirements of modern warehouses.

Ready to amplify your warehouse operations with the effective potential of computer vision? Nextbrain offers AI video surveillance systems for different industries leveraging advanced technologies and powerful intelligence solutions. Connect with our expert professionals to learn more about AI video surveillance systems.