- 7 min read

- Nov 28, 2025

- 0

In a rapidly evolving landscape of logistics and warehouse operations, working efficiently and accurately is crucial to a successful business infrastructure. These facilities handle thousands of packages every day, where manual counting cannot be error-free. The traditional processes mostly introduce delays at receiving docks and shipping stations; in the meantime, barcode systems fail with damaged labels and orientation issues. The inaccuracies mainly occur through inventories, which affects stock availability. The pattern of manual counting processes are not only time-consuming but they come with inaccurate results that may contribute to costly delays.

This blogpost mainly explores a unique technology of AI-Based Counting Systems that reshapes the way businesses tackle package counting and tracking efficiency.

What is computer vision in logistics?

As a subset of AI, computer vision allows machines to analyze, comprehend, and interpret visual data from the surroundings. In a logistics infrastructure, AI cameras enabled with deep learning models can track, detect, and analyze packages automatically, eliminating manual scanning. With the integration of vision AI systems with high-volume facilities, organizations can gain real-time visibility into inventory movement, lowering bottlenecks and ensuring smoother operations. Big logistics companies are now shifting to computer vision solutions to create measurable solutions in boosting productivity.

What necessitates the need for automation in package counting?

Bygone are the days of manual package counting that mostly involved major difficulties. A number of challenges, workers used to face, such as:

- Restricted scalability during peak demand

- Manual fatigue lowers productivity & increases counting errors

- High operational costs

- Data entry delays

Automation through computer vision eradicates the challenges, allowing continuous and real-time package counting with very little intervention.

During loading and unloading at docks, packages are frequently checked at the supplier’s delivery and dispatch. At this time, manual verification not only slows down movement but also raises overall labor costs at the time of peak periods as shipment volumes surge.

According to the latest research conducted by a popular university, it shows that companies and units relying on manual verifications are more likely to accomplish only 65-75% in terms of accuracy. Any kind of mishaps on the package can create a lot of discrepancies that ripple through dispatch tracking, customer delivery, and billing. On the contrary, RFID scanning and barcodes confirm product identity but do not ensure accurate package counts. The errors of inaccurate package count disrupt logistics visibility and result in short shipments.

How is computer vision automating package counting in real-time?

The concept of automated package counting has brought revolution in the logistics industry. The high-resolution cameras continuously monitor conveyor belts, storage areas, and sorting lines. Leveraging deep learning-based object detection models like YOLO, the system recognizes each package based on its unique features, such as low-light environments or size.

Intelligent object detection

Vision AI models trained on large datasets can significantly recognize and separate packages from surrounding infrastructure. Leveraging the system, it can track items across sequential frames to prevent duplicate counts and maintain accuracy when packages vary in size and orientation. It stands out on the advanced image analysis system that reconstructs the complete package boundaries from partial views to ensure the complete counts.

Deployment of the camera

The high-resolution cameras are positioned across facilities in a way to continuously capture image streams as packages move through their field of view. With the automation of the system, there is no requirement of repositioning items for scanning and maintaining uninterrupted material flow.

Processing architecture & system integration

Based on the facility setup, the edge devices can be positioned in distinct locations depending on the infrastructure and network design. Leveraging cloud systems enables model updates and combines analytics across different sites. At Nextbrain, our vision AI platform effectively integrates with the warehouse management system through standard APIs.

What are the applications of vision AI for package counting inoperational environments?

Artificial Intelligence brings in automation in operational environments of industries. Leveraging AI for package counting is empowered and can deliver measurable operational and financial value across logistics networks.

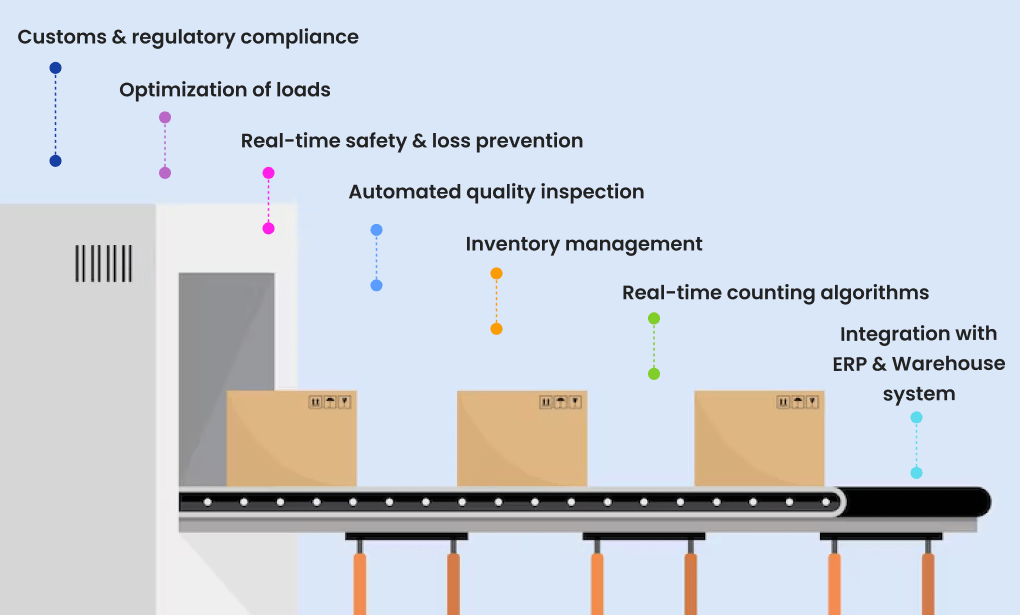

Customs & regulatory compliance

Automating verification, computer vision powered by AI is empowered to streamline several tasks relating to the global logistics system. Logistics working infrastructure mainly depends on documentation matching declared cargo quantities and much more. From generating timestamped image records to synchronizing with shipping and crafting accurate audit reports, vision AI has empowered facilities with a streamlined structure.

Optimization of loads

Computer vision in logistics offers real-time visibility into the overall count data enabling dispatchers to maximize container capacity. The real-time monitoring approach contributes to optimal space utilization aligned with high-throughput environments. The effectiveness gains help in reducing transportation costs and fuel consumption.

Real-time safety & loss prevention

Manual monitoring can often lead to overlooked zones of package movement. On the contrary, AI video surveillance’s continuous visual tracking across arrival, consolidation, and shipment zones can keep a closer look at the packages. The system allows immediate investigation prior to goods leaving the facility. Early detection of routing errors, shrinkage, and inventory discrepancies, facilities can prevent costly expenses.

Automated quality inspection

At Nextbrain, we design computer vision AI systems that are empowered to identify defective packaging, compromised seals, and inappropriate wrapping. Timely detection of package defects eliminates product damage and saves costly affairs. With the automation of verification, defective goods can be isolated prior to shipment or storage in containers.

Inventory management

The real-time count data can be combined with warehouse management and enterprise systems, maintaining precise inventory alignment. The continuous amalgamation between digital records and manual records improves efficiency and accuracy, lowering safety stock buffers. It monitors storage areas and production lines automatically, tracking inventory movement, quantity, and placement without manual scanning.

Real-time counting algorithms

AI technology keeps track of every other object that enters and exits a defined zone. It keeps a close monitoring of the packages, with exact count analysis, and the total is updated in real-time, eradicating manual intervention.

Integration with ERP & Warehouse system

AI video analytics platforms can integrate effortlessly with Enterprise resource planning and warehouse management systems. It ensures real-time synchronization between visual data and operational databases. Each individual detected package or product action captured by cameras is instantly updated in the system for exact tracking. The seamless integration with warehouse management or enterprise systems can be carefully planned for maintaining uninterrupted operations. API-based connections are mainly used for sharing package count information, timestamps, and image records into existing workflows.

Final thoughts

Leveraging computer vision helps in improving the way warehouses manage daily operations. During this era’s high-volume manufacturing as well as logistics environments, computer vision is effectively transforming the way businesses operate. Companies can accomplish real-time visibility, eradicate counting errors, and streamline workflow effectiveness.

The vision AI for high-volume facilities ensures that every package is tracked accurately in real-time, lowering manual efforts and processing delays. With more facilities modernizing their systems, computer vision AI is not only ensuring precision in package tracking but also driving data-informed decision-making across the supply chain. With facilities continuing to scale, embracing vision AI became a strategic step towards higher operational transparency, greater productivity, and long-term competitiveness in the era of smart manufacturing. Get in touch with our specialists to know more.

Frequently asked questions

What is Vision-based package counting?

Computer vision AI-based package counting utilizes advanced computer vision technology to automatically track, detect, and count packages in real time through camera feeds. It eradicates the requirement of manual counting.

How can I integrate AI with existing ERP systems?

At Nextbrain, our AI Video analytics software is designed to seamlessly integrate with warehouse management systems through cloud computing or APIs. The integration allows a range of factors such as automatic data synchronization, ensuring live updates of package counts and inventory levels.

How is automated package counting beneficial to logistics and warehouses?

The process of automated counting helps to lower human error, amplify operational efficiency, and saves labor costs. Providing real-time visibility, the AI-based counting system supports predictive planning and ensures accurate record-keeping across shipping and packaging workflows.

Can the system tackle packages of different shapes and sizes?

Yes, the advanced AI models are seamlessly trained to detect packages in terms of their color and dimensions. The different packaging formats never impact the system’s power of recognition.

How is computer vision AI scalable for large facilities?

Computer vision solutions are highly scalable, enabling multiple cameras and edge devices deploying across different areas. It provides centralized monitoring and analytics for large-scale operations.