- 5 min read

- Aug 8, 2025

- 0

Forklifts are a part of workplaces that regularly deal with heavy equipment and also pave the way to retail store rooms. Forklifts help safely move heavy goods across facilities, warehouses, factories and logistics hubs. It allows for the efficient movement of goods and maximises the use of the space. In infrastructures where forklifts often contribute to workplace incidents every year, safety standards should never be underrated. With facilities becoming widely adopted but facing different challenges, companies are looking for systems that can reliably mitigate risks without any interventions.

In this article, we are going to enlighten readers about how AI is redefining the Forklift collision avoidance system equipped with computer vision technology. Visual intelligence paired with computer vision solutions is the exact fit for the modern industrial infrastructure. A well-planned combination of cameras, real-time processing, and AI-equipped analysis, the Forklift Collision Avoidance System provides a more accurate and effective way to monitor forklifts’ surroundings.

Pedestrian safety around forklifts is always a challenge

Though forklifts seem small, their weight can be huge, up to 10,000 lbs in certain cases. Forklifts have the power to cause severe injuries such as fractures, strains and muscle damage. Several admin controls across forklifts, like restricted areas with forklifts and pedestrian mapping, were adopted to mitigate any kind of accidents.

Some of the major pedestrian high-risk situations involve:

- In scenarios of narrow aisles, forcing forklifts and pedestrians inside close proximity with little room can turn into a great challenge.

- Several blind corners result in pedestrian accidents.

- Rear visibility is restricted in scenarios of reversing forklifts.

- Sometimes, distracted workers remain unaware of their surroundings.

With the implementation of computer vision, Artificial Intelligence can provide a more comprehensive understanding of the risks.

The role of computer vision for forklift collision avoidance systems

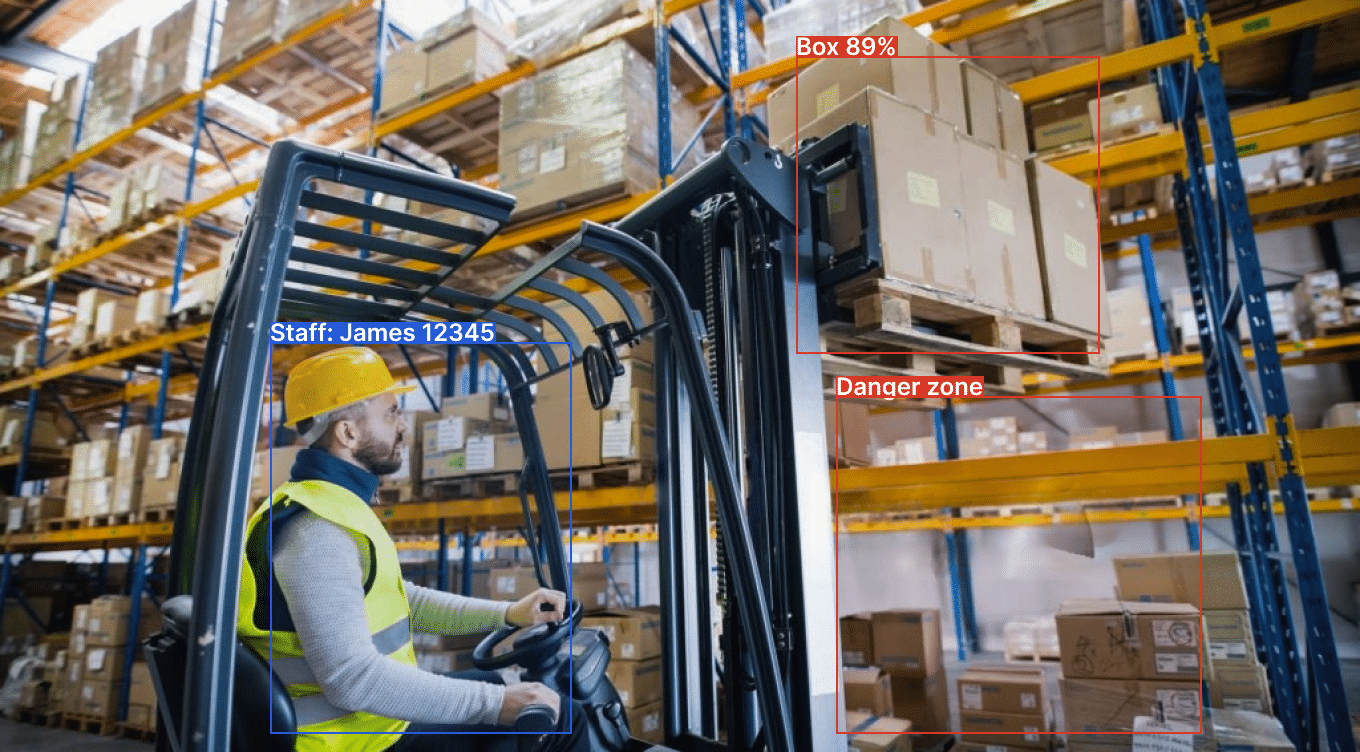

When it comes to pedestrian and forklift interactions, safety is the primary priority. Without solely depending on fundamental distance measurements, authorities can analyse visual data to comprehend the forklift’s environment in real time. Video cameras equipped with computer vision technology can identify people, vehicles, racks, pallets, and classify them depending on their features. AI models that are trained in industrial environments can trigger alerts on the detection of any kind of unsafe behavior or fault detection.

Improving the forklift collision avoidance system with AI computer vision

Nextbrain’s AI-powered Forklift Accident Prevention system helps EHS departments that are always looking for an improved safety system.

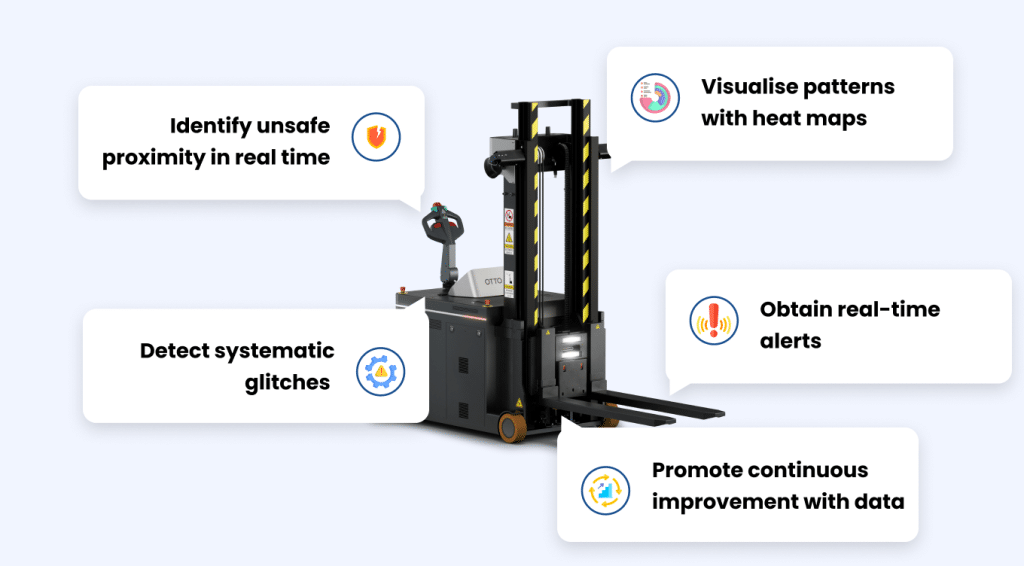

Obtain real-time alerts

On detection of any intrusions across restricted areas, Nextbrain sends immediate notifications to the authorities. It seeks prompt action and prevents any kind of mishappenings.

Identify unsafe proximity in real time

Leveraging computer vision AI, any pedestrian or operator’s proximity to the forklifts can be easily identified in real time. It immediately sends notifications & triggers an alarm seeking immediate action.

Detect systematic glitches

There are times when unsafe events can change the scenario, which are mostly underestimated. With heatmaps, these situations can be tackled.

Visualise patterns with heat maps

Across a workplace facility, vision AI-generated heatmaps can be used to detect behaviours that are potentially harmful across forklifts.

Promote continuous improvement with data

Gathering large volumes of data regarding forklift-operator interactions, the facility teams can validate the importance of the present controls. It offers insights to improve continuously.

Reason behind industries embracing vision AI-based forklift collision avoidance system

The traditional forms of sensor-based systems often come with limitations. However, this isn’t the scenario with advanced intelligence. Computer vision powered by AI administers real-time image recognition, allowing forklifts to seamlessly detect obstacles and unsafe conditions.

With time, it reduces the risk of damage to goods, diminishes downtime and ensures compliance with safety regulations.

Higher workplace safety standards

With Computer Vision for Forklift Safety, facilities can maintain proper safety procedures and guidelines across workplaces. Besides offering a safer workplace, it offers a secure ground for operators and staff so that they can work efficiently.

Effective operational awareness

With vision AI, operators can have a comprehensive view of the surrounding activity without depending on guesswork.

Less downtime & collisions

Real-time alerts assist in preventing incidents from escalating with prior detection. Not only does it prevent accidents, but it also keeps operations moving without costly disruptions.

Final thoughts

Forklift safety is not just about visibility vests but also mirrors. By embracing computer vision for forklift safety and collision avoidance, several workplaces and facilities can aim towards a smarter infrastructure. Data-driven intelligence helps make informed decisions deliberately. The traditional systems were faulty, and resolving those issues was necessary.

The future of industrial safety is not just human-aware but also machine-aware, and it is already here.

Are you ready to learn more about forklift safety and accident risk reduction with Computer vision? Reach out to our professionals and explore this technology to boost your business prospects.

Frequently asked questions

What is meant by forklift collision avoidance systems with vision AI?

A forklift collision avoidance system equipped with computer vision AI utilises AI-powered cameras to identify people, obstacles and other vehicles in real time. It helps to analyse visual data for warning operators to take automatic action and prevent collisions while improving workplace safety.

What type of forklift hazards and mishappenings can computer vision detect?

Computer vision is capable of detecting forklift-human interactions, workers in blind spots, other forklifts & vehicles, unsafe behaviours like speeding in congested zones, and structural hazards.

How does the AI-powered computer vision system work to prevent potential collisions?

Administering real-time alerts, the AI Video analytics software system uses visual indicators, data algorithms and audible warnings to prevent any kind of incidents. In situations, it can autonomously slow down the forklift to prevent an accident.

How does AI-powered computer vision technology contribute to accident risk reduction?

By administering real-time situational awareness as well as proactive alerts, the system assists in preventing collisions prior to their occurrence. It contributes to reduced downtime, fewer injuries and an advanced safety culture.

What are the industries that are going to benefit from this technology?

Several industries that have operations related to forklifts are going to benefit from the AI-powered computer vision. The industries mainly involve automotive, manufacturing, food & beverage, construction, and retail industries.