- 6 min read

- Mar 21, 2025

- 0

Traditional manual inspection techniques sometimes fall short trying to keep pace with the sheer volume of data. Production downtime, safety events and quality control glitches are significantly affecting the operational efficiency. Computer vision provides a powerful tool for addressing these challenges. Establishing a scalable computer vision platform is relevant to widespread adoption across several industries. Computer vision is empowered with the potential to solve different challenges and vision AI is predicted to boost production by nearly 40%.

In this blogpost, we are going to explore the power of computer vision in manufacturing and how it has helped in transforming the industries. Lets take a look at the different aspects of building scalable Computer vision in defect detection for large scale industries. Artificial Intelligence is emerging as one of the largest technological developments across the globe. Businesses are beginning to realize that the past massive scaling models using manual supervision are becoming outdated and have low performance. Using computer-vision models, businesses can streamline their real business operations.

In this blogpost, we are going to delve deeper into the various technology solutions for scaling at different levels. Scalability is crucial for enterprise-ready solutions.

What is exactly implied by a scalable computer vision system?

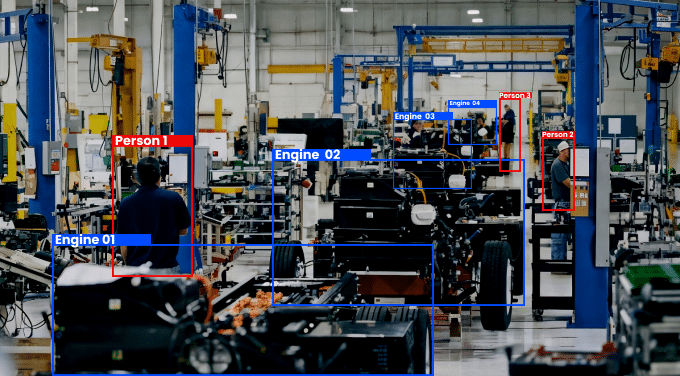

Computer vision is considered as a subset of Artificial Intelligence that enables cameras for identifying people, objects and events in real-time. Scalability is all about enabling AI solutions for reaching its potential. Advanced computing infrastructure is required to process continual visual data enabling deployment. User-friendly computer vision platforms can help enterprises with scaling AI solutions.

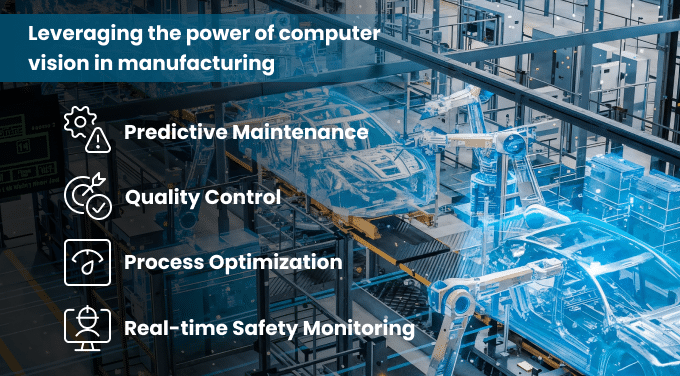

Leveraging the power of computer vision in manufacturing

Computer vision technology enables machines to gather and analyze image/video data at a much higher speed and accuracy. A number of excellent features like object identification, image segmentation, real-time monitoring, data visualization and image recognition are the various major instances of computer vision. In this context, we have discussed the revolutionary transformations that vision AI models have brought to a manufacturing infrastructure.

Predictive maintenance

In a manufacturing industry, proper maintenance is crucial to the effective well-being of the factory. Timely maintenance and health check-up of the equipment are important with ensuring zero downtime. However, conventional methods of maintenance are time-taking and require expenses too. Machine learning tools can be harnessed to evaluate video footage in real-time. As per the latest study by McKinsey it can be stated that predictive maintenance enabled by AI can save maintenance costs by up to 40% reducing downtime by 50%.

Quality control

Artificial Intelligence for computer vision assists in identifying defects in production lines in real-time. Computer vision for quality control has a major impact on the manufacturing industry. It enables precise detection of defects in manufacturing equipment by analyzing images gathered from cameras effectively lowering human error and enhancing product quality. It rapidly analyzes products on a production line automatically identifying defects without the need for manual inspection. These advanced systems provide immediate feedback on detected defects allowing adjustments to the production process.

Process optimization

Computer vision powered by AI helps manufacturing businesses to assess the smallest product details inspecting for faults and glitches for reducing the frequency of errors. Leveraging computer vision models can help in maximizing operational efficiency and minimizing downtime. It is harnessed to gather process sequence information from image/video data by IP cameras. It analyzes the extracted data and generates valuable insights in real-time. Vision AI in manufacturing industries proves beneficial in offering highly productivity results, improved product quality and reduced expenses.

Real-time monitoring of safety

Priorities should be given to safety compliances inside a manufacturing facility. Any kind of unsafe worker’s behavior, lack of PPE compliance and hazardous conditions, are proactively identified. Computer vision object detection systems are capable of detecting hazardous areas, possible risks and people without proper PPE.

What are the limitations of scaling computer vision in factories?

In distinct verses, Computer vision in manufacturing comprises the power to bring about major transformations.

Computational resources

Leveraging advanced algorithms and GPUs are crucial to managing the system. Likewise, visual input data processing needs large computational potential. Edge computing can assist lower this load, however, it comes with major challenges associated with the deployment of advanced technology at the edge.

Model training

Vision AI is still in the experimental phase and computer vision models work with large datasets. Obtaining and labelling this data can be time-consuming and expensive. Implementing trained models into systems requires effective expertise. However, ensuring their consistent performance requires a strong model management and deployment flow.

Integrating with existing systems

A manufacturing factory thrives on an intricate infrastructure inside the operation network. Seamless integration with existing factory systems is valuable; however, it comes with major challenges like interoperability and data exchange.

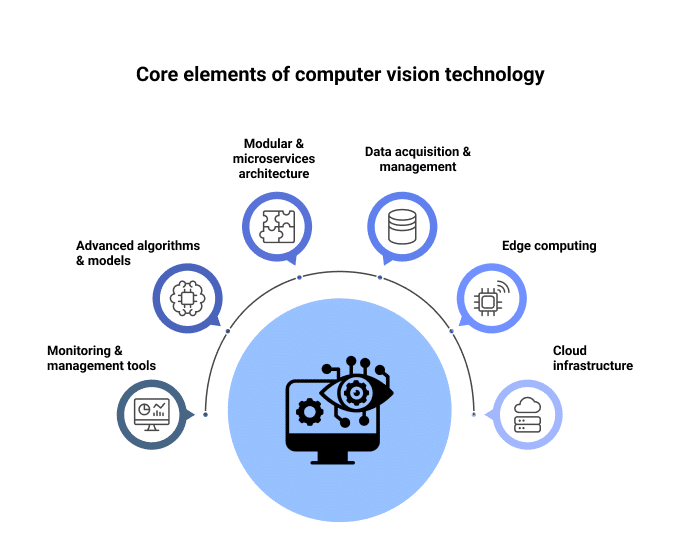

Core elements of computer vision technology

Herein lets take a look at the key elements of computer vision technology and how it plays an effective role in scalability of computer vision systems.

- Monitoring & management tools

- Advanced algorithms & models

- Modular & microservices architecture

- Data acquisition & management

- Edge computing

- Cloud infrastructure

What is the future of a scalable computer vision system?

For a long term value, a computer vision platform helps manufacturing organizations implement data-driven processes who find it easier to navigate uncertainties while staying ahead of demand. While discussing its future, computer vision platforms are likely to shimmer with its potential to seamlessly integrate with advanced AI models, edge computing and real-time processing. It is important to maintain constant improvement based on the latest developments in AI for computer vision and machine learning. Several platforms enable businesses to integrate their existing analytics tools amplifying their ongoing analytics procedures.

Establishing a scalable computer vision platform is considered as a strategic investment for large-scale manufacturing operations. It allows manufacturers to go beyond the constraints of traditional techniques effectively improving quality, security and effectiveness.

Final thought

In order to completely realize computer vision technology, manufacturers are capable of making different investments in scalable systems. Computer vision powered by AI is empowered with the immense potential of real-time surveillance, analyzing image/video data and streamlining manufacturing processes with automation. Managing and optimizing different applications across different locations needs advanced data. Nextbrain offers a transformative approach for businesses managing and scaling the entire vision AI application for streamlining processes. Our AI Video analytics software is specially designed to automate operations and offer real-time monitoring of the manufacturing processes.

Do you want to embrace a scalable computer vision solution for your manufacturing industries? Feel free to connect with our experts and know more about vision AI.