- 5 min read

- Dec 9, 2025

- 0

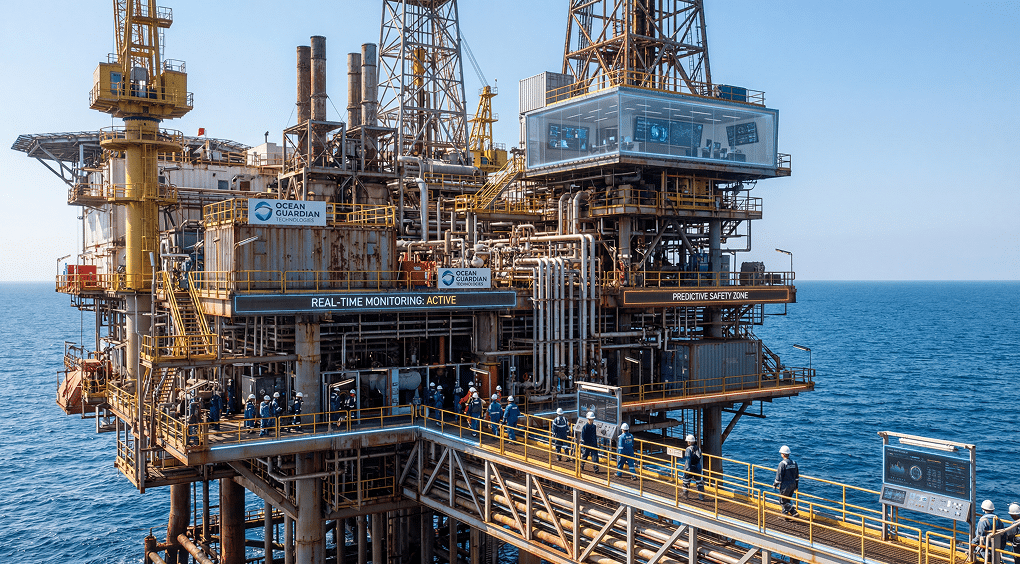

A major part of the offshore operations is all about oil rigs that carry inherent risks owing to the harsh environmental conditions as well as complex machinery. The oil rigs are designed in a way that they are run by skilled oil rig workers for specialized tools. These tools mainly involve drilling apparatus, pumping systems, pipeline networks, and advanced control mechanisms. There are times when workers face equipment malfunctions and drilling glitches, especially when it comes to inherently hazardous operations across offshore installations.

As per the latest US Bureau of Labor Statistics, the fatality rate for gas and oil extraction is nearly more than the average for all industries. Safety analysis reduces operational disruptions, prevents environmental damage, and safeguards the company’s reputation.

In this blog, we are going to explore the way computer vision in the oil & gas industry is improving oil rig safety right from real-time equipment monitoring to predictive maintenance. The technologies are transforming performance in high-risk environments and elevating safety compliance in such zones.

How do the oil rigs work?

Behind every oil rig is a complicated engineering that is designed for extracting oil and gas from beneath the earth’s surface. Every oil rig comes with a precision-engineered drilling system that has multiple functionalities to proceed. One of the most relevant critical processes in oil rig work is mud circulation, where specially formulated drilling fluid cools the drill and transport formation cuttings to the surface. The oil rigs feature a wide range of pipeline networks that assist in maintaining pressure and flow across the operation.

Managing the complex systems, oil rig workers ensure that oil rig safety protocols are followed to reduce the risks of tool failure and blowouts. Ensuring continuous oil rig monitoring in real-time with advanced technology like computer vision and AI is essential to workplace safety. In this context, we are going to focus on the major benefits of AI safety monitoring on oil rigs, where readers can get a complete understanding of how computer vision is transforming oil rig safety monitoring with advancements.

Core benefits of computer vision systems in oil rig monitoring

Predictive maintenance and data-driven insights

Predictive maintenance is defined as the utilization of AI and analytics for predicting equipment failures and ensuring prompt maintenance. The computer vision in the oil & gas industry is capable of detecting hazards such as fires, gas leaks, suspicious behaviors, and PPE violations. On analyzing video feeds, it recognizes early signs of tool corrosion, wear & tear and vibration anomalies. Amalgamated with data-driven analytics, the system assists operators in scheduling timely repairs, lowering downtime, and preventing incidents. It elevates decision-making and caters to efficient operations.

Leveraging advanced AI algorithms such as recurrent neural networks, supervised learning, and anomaly detection algorithms, the system ensures the smooth operation of oil rigs while elevating asset lifespan.

Strengthening workers’ safety with monitoring

The continuous presence of hazardous materials, high-pressure systems, and moving machinery makes oil rigs more prone to a hazardous work atmosphere. Computer vision powered by AI elevates safety by actively monitoring workers, automatically verifying the utilization of PPE compliances, and detecting any kind of safety breaches. Our software assists in reinforcing safety regulations across oil rig infrastructure, elevating safety standards in real time.

Integration with IoT devices

With the integration of IoT devices combined with AI, the oil rig operations can transform operational efficiency, empowering informed decision-making. It revolutionizes management and facilitates condition-based maintenance, enabling targeted interventions.

Hazard detection systems

The drones integrated with computer vision provide comprehensive surveillance capabilities. Drones equipped with vision AI-driven cameras are capable of inspecting underwater structures and areas that become difficult for human inspectors. The systems can scan hazards in real-time, enabling rapid responses and preventing small issues from escalating into more serious incidents.

Automated maintenance scheduling

Predictive capabilities paired with computer vision algorithms can automate the maintenance process by analyzing real-time performance data. As equipment shows signs of wear or malfunction, the system is capable of triggering maintenance alerts. The automated scheduling prevents unnecessary repairs and keeps equipment running improving oil rig safety.

Final thought

The combination of AI technologies with computer vision has brought relevant advancements in effectiveness. The technology is capable of transforming the way oil rigs are managed and maintained. By providing real-time hazard detection, predictive maintenance, and real-time monitoring, computer vision continues to play a prominent role in ensuring oil rig safety. With offshore operations becoming more complex, integrating computer vision with advanced analytics helps to empower industries to create smarter and efficient rigs. As a proactive safety culture, computer vision for real-time monitoring and maintenance sets forth a complete culture of minimal risks, optimized performance, and enhanced productivity. Get in touch with our specialists to know more.

Frequently asked questions

What is computer vision in oil rig safety?

Computer vision leverages AI-powered cameras for automatically monitoring operations, scanning hazards, and analyzing equipment conditions in real-time. From improving safety compliance to reducing workplace risks, our computer vision system covers all safety-related standards to create a safer workplace.

How can computer vision help with predictive maintenance on oil rigs?

Computer vision algorithms analyze wear, patterns, and tool performance to predict early equipment glitches/failures. Helping crews schedule maintenance proactively, computer vision powered by AI prevents costly downtime.

How does computer vision support data-driven decision-making in oil rigs?

Gathering detailed operational data, computer vision offers insights into safety trends, equipment health, workforce performance, and failure patterns. It allows smoother decisions and smarter decision-making.

What alerts can we expect from computer vision for rigs?

The AI Video analytics software is capable of sending real-time warnings through alarms, dashboards, and mobile alerts whenever different safety glitches are detected.

How can computer vision improve compliance with regulatory standards?

The automated monitoring ensures adherence to safety protocols, administering audit-ready records, and supports compliance with OSHA and several other regulations.