- 6 min read

- Nov 28, 2024

- 0

One of the effective advancements of AI is that the world is experiencing computer vision AI. Computer vision has created relevant potential for innovation and growth effectively revolutionizing the industry operations. With AI changing the rules of competition, companies and organizations in terms of business are racing to build custom computer vision applications leveraging the power of AI.

Artificial Intelligence has reshaped the way technology works, and now businesses are trying to seek newer ways to generate value and focus on modern technological advancements. Recently, it has come to notice that oil and gas companies are investing in data science and machine learning to have greater ROI. To improve oil well finding and precision drilling, computer vision AI paired with machine learning is well used.

AI and machine learning have immense capabilities in the gas and oil industry. From speeding up decision-making and reducing overall costs to adding capacity and capability and enhancing quality, they have proved beneficial in many ways, creating an elaborate digital space.

In this blog post, we will take a closer look at the major applications of computer vision AI in the oil and gas industry. The context will shed light on the use cases of computer vision in the oil and gas industry.

What are the technology trends of AI in the oil and gas industry?

Breakthroughs in computer vision enable seamless use of distributed computer vision applications. Technological advances make it possible to build large-scale deep-learning applications with a large number of connected endpoints. Contrary to conventional sensors, cameras administer a contactless process providing rich information regarding complex situations.

Embracing AI and ML algorithms requires a fundamental change in the way operations are carried out.

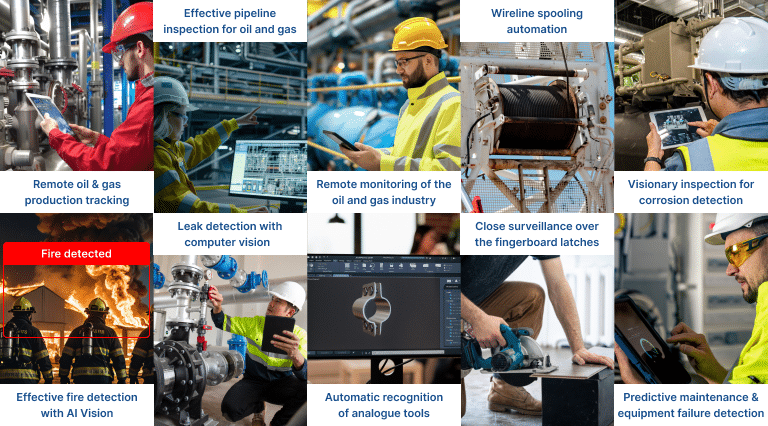

Major use cases of computer vision in the oil & gas sector

Remote oil & gas production tracking

Leveraging AI algorithms and machine learning techniques helps in real-time monitoring of oil and gas facilities. AI video analytics software technology can keep track of the status of load pumps for improving oil and gas output. High-performance and low-cost sensors have the potential to drive the digital transformation of the oil and gas industry by enabling high-value information from big data.

Effective pipeline inspection for oil and gas

By harnessing computer vision, deep learning processes assess large-scale systems by drawing critical insights from camera-based remote sensing data. For heavy oil and gas facilities, pixel-level processing using deep learning models is capable of pinpointing the precise position and severity of damage within a short period.

Remote monitoring of the oil and gas industry

Real-time oil and gas monitoring with cameras can be used for automating and digitizing oil development sites for maintenance of offshore oil and gas fields. These systems aim to increase oil and gas productivity by monitoring and predicting the condition of load pumps with ML techniques. With distributed systems, it can extract high-value information from big data.

Wireline spooling automation with computer vision

Oil and gas industries are teeming with wirelines specifically used for reservoir assessment and well indulgence. As the tool string is retrieved from the well, it should be tackled in a proper way to avoid glitches. Improper handling of the spool can lead to severe cable damage.

Visionary inspection for corrosion detection

Corrosion is considered one of the major defects in structural systems. It can pose significant risks when it is left unattended. Conventionally, inspection tasks used to be performed periodically by manual labourers which could potentially lead to errors. Manual errors are unavoidable and the manual interpretation process is quite expensive, subjective and time-consuming. Deep learning methods help in analyzing the video images of cameras for automating inspection tasks. Computer vision is successfully applied in use cases for automatic rust detection resulting in cost savings, informed decision making and many more.

Effective fire detection with AI Vision

Workplace safety is of primordial importance when it comes to the oil and gas industry. There are times when these facilities are highly vulnerable to theft of important equipment, vandalism and sabotage. These zones are prone to groundwater contamination through leakage which results in criminal charges, fines, and a terrible impact on reputation. Artificial Intelligence is capable of monitoring unattended operation sites round the clock for security concerns like intrusion and sending instant alerts relating to concerned authorities.

As a result of harsh weather conditions, hazardous conditions, and extreme operating conditions, the oil and gas industry confronts the constant risk of fires, spills, and explosions, risking worker’s lives. Computer vision algorithms are capable of helping in oil and gas site inspections with real-time surveillance. Video analytics from the camera feed can adhere to safety procedures such as preventing slip and fall accidents due to slippery surfaces.

Leak detection with computer vision

Machine vision can be leveraged to detect methane gas emissions utilizing regular infrared cameras. With the automated approach simplifying the leak detection analysis with very high accuracy, it becomes easier to detect leaks in an oil and gas infrastructure. Automated processes streamline the analysis of leak identification. It comes with accurate results of 95% to 99%. Convolutional neural network processes can be used and trained for automatic identification.

Automatic recognition of analogue tools

Vision AI can be trained to read analogue gauges at power substations. Computer vision algorithms use colour segmentation to detect the position of the pointers and scale marks. The cameras equipped with vision AI are used to read oil level gauges and winding temperature gauges automatically. Its effective application delivers more accurate results and assists in preventing dangerous accidents.

Close surveillance over the fingerboard latches

A major part of performing a safe drilling rig is keeping a close eye on the fingerboard latches. With the implementation of Computer Vision for the Oil and Gas industry, companies can have real-time surveillance across different fingerboard latches. Harnessing computer vision models trained on the latch, vision AI solutions can provide visual confirmation of latch conditions in real-time.

Predictive maintenance and equipment failure detection

Across oil and gas plants, deep learning models can seamlessly detect tool failures. Subsequently, custom neural networks are effectively trained for detecting anomalies at the time of automated equipment inspection. Real-time monitoring of equipment performance can predict potential failures enabling proactive maintenance to diminish overall downtime and prevent accidents.

Wrapping up: Unleash the potential of computer vision

Computer vision solutions can provide different benefits right from improving worker safety, to lowering operational costs and optimizing core processes in the oil and gas industry. Several oil and gas companies would need computer vision systems as a result of their critical nature and specific operational workflows. As a leading computer vision development company, Nextbrain comprises a dedicated team of professionals having many years of expertise in creating high-value applications for industries. To know more about computer vision and its real-world applications, connect with our professionals.