- 8 min read

- Sep 3, 2025

- 0

Global energy generated by solar power systems has become a sustainable power source worldwide. The fast-evolving world of renewable energy sources is all about maintaining large solar farms and creating focused infrastructure. Those days are over when manual inspection of solar farms potentially involved hazard-prone tasks, manual labor, and unavoidable errors. With immense benefits, the system faces various challenges due to defects resulting from weather conditions, including discolorations, microcracks, and extreme temperatures, among others. Several other limitations could not be denied, such as accessibility issues, data variability, and safety concerns.

With the advent of computer vision AI in solar energy, solar farm companies embrace an effective approach to identifying minor and major defects in PV modules of solar systems.

Drones are making a significant difference in AI inspections

Efficient in detecting & predicting defects, drones are making huge contributions for different applications across solar panel inspection, pipeline monitoring, power plant inspection, and many more.

In this context, it is important to understand the multifaceted complexities of manual solar panel inspections.

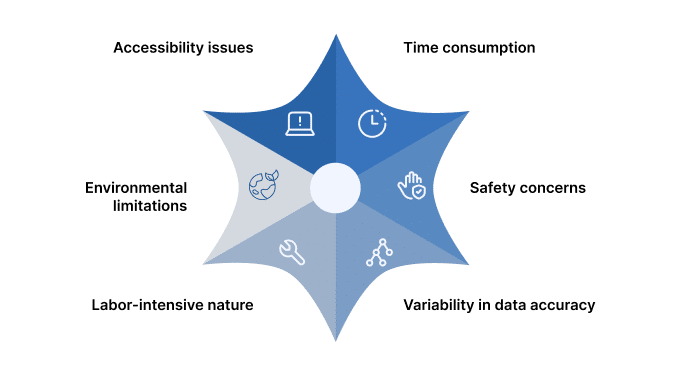

Comprehending the difficulties of manual solar panel inspections

Solar farms, however, aren’t free from challenges. A number of factors are involved in the process.

Time consumption

The manual inspection of solar panels has always been a time-intensive process. The task involves exposing workers to potential hazards and manually documenting findings, which additionally impacts the efficiency of the inspection process.

Safety concerns

Traditionally, manual inspections often involve workers climbing onto rooftops and structures where solar panels are installed. They expose themselves to potential hazards like electrical shocks and safety risks.

Variability in data accuracy

Resulting in inconsistencies, manual inspections often result in issues in data accuracy. Different factors, such as experience levels, lighting conditions, as well as subjective lighting, can influence the consistency of the gathered data.

Labor-intensive nature

Inspections performed manually are often labor-intensive and are an expert’s job. It requires skilled personnel to visually inspect individual panels and record data.

Environmental limitations

Severe weather conditions, such as rain, high temperatures, and heavy moisture, can impact the feasibility and safety of conducting entire inspections.

Accessibility issues

Certain panels of solar farms are situated across areas that are not only difficult to access but also make it difficult to conduct inspections.

How computer vision AI plays a major role in precision detection

While drones capture footage in detail, Vision AI-powered systems add intelligence to the process. AI models are designed in a way that can analyze images in real time, detecting anomalies with a level of precision unmatched by manual inspections. It can predict future failures using historical data trends and additionally segregate glitches as per their severity. Therefore, predictive maintenance contributes to reducing costs, improving the lifespan of solar panels.

As our Vision AI developers focus on the system, it is relevant to acknowledge the process by which computer vision-supported AI drones are influencing solar panel infrastructure is key to a successful solar farm business protocol. Using deep learning algorithms helps to examine the condition and performance of solar panels.

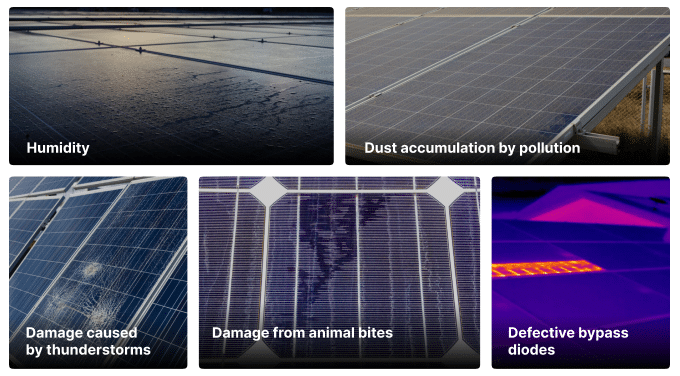

What are the major limitations in solar panels that resulted in embracing AI-powered drones?

Solar farms often suffer distress resulting from extreme weather conditions and situations that are unavoidable. Mentioned below are some of the major problems that AI-powered drones can autonomously detect. It identifies issues such as:

Humidity

AI-powered drones are capable of detecting spaces that have higher humidity and moisture content. It generally focuses on weaknesses in the panel’s sealing and scan areas that are prone to corrosion and electrical faults.

Dust accumulation by pollution

The combination of AI drones and high-resolution cameras are capable of scanning any dust buildup on solar panels. Pollution and dust accumulation can impact the efficiency of their operations.

Damage caused by thunderstorms

Subsequent to prolonged weather conditions, drones can quickly evaluate damage caused by debris and other impacts. The cracks in panels and other structural damage can lead to potential inefficiencies. AI-powered drones are the best solution for smart solar farming.

Damage from animal bites

There are times when animals can cause damage to the panels causing animal bites and scratches. AI drones can easily detect them and notify authorities for prompt action.

Defective bypass diodes

Drones equipped with specialised sensors and AI video analytics are capable of detecting defects in solar panel wiring configurations, focusing on areas of incorrect wiring and malfunctioning bypass diodes. It can cause electrical inefficiencies and failures.

Process followed by AI drones improves the analysis of solar panel defects

Capturing images & footage

Drones that are equipped with high-resolution cameras mounted across different locations, capturing images as well as videos of solar panels. The visual data administers detailed visual information regarding the panel surfaces.

Gathering data

Visual data gathered are processed for scanning any kind of anomalies like dirt, cracks, and hotspots. These are generally processed through computer vision algorithms and impact the efficiency of the solar panels.

Detecting defects

Leveraging computer vision models, data can be analyzed for detecting any kind of defects on the surface of the panels. The process involves edge detection, pattern recognition, as well as image processing methods.

Classification & analysis

Harnessing deep learning algorithms, the vast datasets of normal and problematic solar panels are capable of segregating between normal and abnormal conditions. It enables for exact classification of issues and the seriousness of any conditions.

Predictive maintenance

With the continuous pattern recognition, computer vision systems have the potential to predict future glitches and involve ways to ensure efficiency. It prevents future issues and increases the panel’s efficiency.

Automated reporting

Depending on the analysis that focuses on areas that require attention, computer vision AI systems generate reports. It assists operators in quickly identifying issues and reducing overall downtime.

Integration with the maintenance system

It can be seamlessly integrated into a broader maintenance system, enabling for automated replacements, autonomous scheduling of repairs, and so forth.

What are the real-time insights for smarter decision-making?

Drones and Vision AI combined do not stop at detection as they provide actionable insights in real time. It has the potential to prioritise repairs, schedule predictive maintenance, and amplify comprehensive energy output. Vision AI algorithms have brought in a new wave of digital transformation for the solar industry.

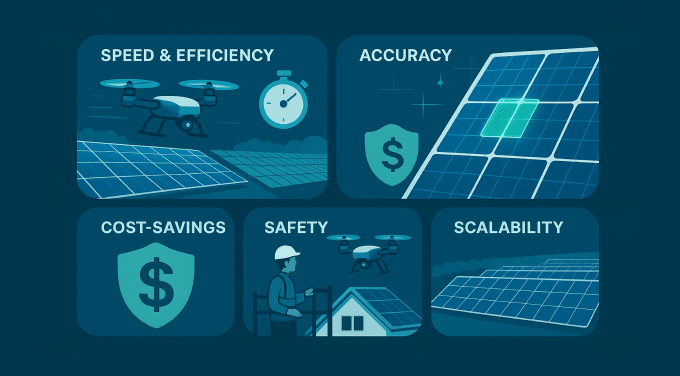

Why drones with Vision AI are considered a game-changer

Contrary to traditional manual inspections, computer vision AI-powered drones provide:

Speed & efficiency

Encompass hundreds of acres in minutes

Accuracy

Vision AI is capable of scanning hidden anomalies invisible to the naked eye.

Cost-savings

Diminish labor costs and avoid expensive panel replacements.

Safety

Eradicate risks of human inspectors working in hazardous environments

Scalability

Effectively ideal for both rooftop solar setups and large-scale solar farms.

The Future of Solar Panel Inspections

With the adoption of Computer vision AI in solar panel inspections, the energy maintenance practices provide a thorough data analysis. It brings in a new era of precision and cost-effectiveness in managing solar energy systems. It helps to improve energy production efficiency and contribute to a resilient energy infrastructure.

Final thought

The integration of computer vision-powered drones in solar inspections marks a pivotal shift towards faster and sustainable energy management. By amalgamating the precision of AI with the agility of drones, solar farm operators can offer unparalleled accuracy but also unveil predictive maintenance. Our drones utilize advanced technologies to range from disconnected panels to thermal hotspots, identifying defects precisely.

Are you prepared to benefit from AI-powered drone inspections to improve your solar energy efficiency? Get in touch with us now to see how we can help you improve efficiency, reduce expenses, and contribute to a greener future!

Frequently asked questions

What is considered Vision AI drone-powered solar panel inspections?

With the use of drones equipped with computer vision and AI Video analytics software, one can scan solar farms, effectively detecting defects and anomalies in real-time.

What kinds of glitches can Vision AI drones detect?

It can identify hotspots, micro-cracks, dirt accumulation, wiring faults, and thermal defects. Several other kinds of glitches can be addressed too, such as extreme weather conditions.

Do you consider drone-based inspections as cost-effective?

Yes, they just not only reduce laboring costs but also prevent any kind of costly panel replacements, advancing the energy output and ROI.

Why are vision AI drones favoured for solar panel inspections rather than traditional processes?

Contrary to manual processes, computer vision AI drones provide higher accuracy, faster coverage, cost savings, and safer inspections.

What are the future prospects of vision AI in solar energy?

With major advancements across predictive analytics, IoT, and automation, AI-powered computer vision are transforming the solar farm infrastructure, ensuring maximum efficiency and minimal downtime.