- 6 min read

- Aug 21, 2023

- 0

In the last few years, the manufacturing industry has undergone a major revolution. Presently, the fourth Industrial Revolution has become more profound which has indirectly impacted the machine learning system. Machine learning is considered a powerful tool for the industrial revolution that accounted for 17% of global GDP in 2021. Smart manufacturing has been transformed by machine learning techniques. With the increased usage of machine learning, the primary causes of production losses have been reduced resulting in a changed landscape.

Manufacturing is one of the popular industry verticals where machine learning has gained a competitive advantage over others. As a result of emerging technology developments, one can have significantly minimal machine downtime, improved labour, and enhanced productivity. In this blog post, we will understand the various basic blocks of machine learning, machine learning app development, its use cases in manufacturing and how it has been able to boost its journey in digital transformation.

What do you mean by machine learning?

As delineated by Google, Machine learning can be defined as a subset of artificial intelligence that allows a system to autonomously learn as well as advance neural networks and deep learning without any programming by feeding it large amounts of data.

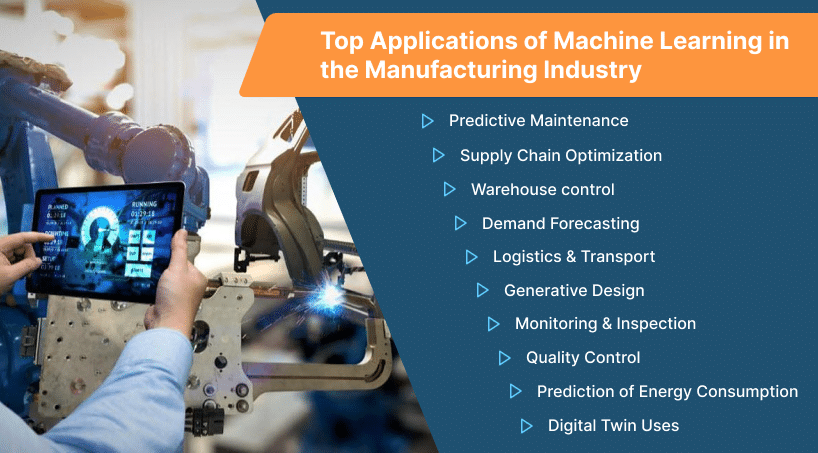

Top applications of machine learning in the manufacturing industry

In order to have a complete understanding of the relationship between machine learning and manufacturing industry verticals, we need to look at the major applications of Machine Learning in the Manufacturing industry.

Predictive maintenance

Predictive Maintenance is considered the fastest-growing manufacturing machine learning instrument. As per the latest statistics, it is seen that predictive maintenance evinced a projected increase in its market value of 38% right from 2020 to 2025. Predictive maintenance employs algorithms for forecasting the next failure of an element. Even with the robust algorithm, predictive quality analytics are effective. For a successful manufacturing software development solution, developers adopt advanced software development tools combined with modern technologies.

Supply chain optimization

The supply chain is considered an incomparable part of manufacturing industry verticals. The various machine learning technologies are revolutionizing the elements of a cognitive supply chain. It will, in turn, embellish several supply chain areas such as warehouse control, demand forecasting, logistics & transport.

Warehouse control

Warehouse control allows rapid replenishment of goods by assisting stock control with deep-learning computer vision systems.

Demand forecasting

It studies the client’s behaviour and offers preferences using time series analysis, natural language processing and feature engineering.

Logistics & transport

In logistics and transport optimization, machine learning algorithms allocate as well as evaluate the optimal route for transportation and shipping.

Generative design

Machine learning has major applications in generative design for transforming time-consuming engineering design processes into sophisticated product design. Machine learning offers generator and discriminator models for developing new designs for specific products and differentiating between real and generated products. One can train deep learning algorithms for identifying design processes.

Monitoring & inspection

The process of inspection of tools and monitoring of processes harnessing computer vision is a popular machine learning application in manufacturing. The machine learning-based algorithms often perform high throughput part inspection and cost-effective sensors like RGB cameras. Additionally, computer vision techniques allow premium quality continuous process monitoring.

Quality control

Machine learning has the capability to recognize the main source of process-driven production losses utilizing varied tailored machine learning algorithms. It is popularly known as root cause analysis which is supported by machine learning mechanisms. In situations of warnings and alerts, it notifies production personnel of an impending problem and easily exchanges relevant data for the prevention of losses.

Prediction of energy consumption

In production, forecasting energy utilization is significant owing to its varied benefits. In the case of startups, it helps industry owners in planning future energy requisites. This is important for ensuring that the industries have essential resources to meet demands. In order to maximize effectiveness, one needs to consider the energy consumed.

- Autoregressive Models: These models are influential for defining power consumption, cyclicity, trends, and seasonality.

- Deep Neural Networks: Similar to autoregressive models, deep neural networks can be trained to extract features automatically from input data.

Digital twin uses

Machine Learning-enabled digital twins are highly beneficial to manufacturers for carrying out instant diagnostics, assessing, production processes, and making performance predictions. Digital twins can easily revolutionize development practices at the time by offering production, full design, and operational customization. Manufacturers and factory owners are using technological advancements across all manufacturing phases right from product design to completion.

Real-life examples of machine learning in manufacturing

Rolls royce

Germany’s Rolls Royce aircraft design has been incorporating ML into its processes to a much greater extent. The technology enables a jet engine to communicate with other engines and customer airlines. Additionally, machine learning software enables a jet engine to learn from its experiences.

Schneider electric

Schneider Electric is a global power management company employing a predictive Internet of Things (IoT) analytics solution depending on Microsoft Azure Machine learning and Azure IoT Edge for remotely monitoring and configuring oil pump settings in production plants.

Siemens

Siemens introduced the Anomaly assistant application that utilizes machine learning algorithms to teach AI which anomalies are relevant to business objectives. The ML algorithms are trained utilizing process data and can recognize the problems impacting the economic effectiveness of a given facility. The ML-enabled app dashboard offers plant operators the flexibility to refocus Artificial Intelligence to recognize the most relevant anomalies. The application can be installed as a cloud and within a customer’s existing infrastructure. The program is available on AWS (Amazon Web Services), for virtual machines it is ESX and Hyper V; for on-premise deployments, it is SIMATIC Box PC. The cloud-based computing with AWS enables Siemens and its customers to interact seamlessly.

Conclusion

Machine learning in manufacturing has become a strategic prime concern for leading companies. Many have built professional centres of excellence to support the implementation efforts. The success of the journey from digital dashboards to completely fledged machine learning is based on multiple factors. If you are looking for an ML-enabled software solution for your business, then you need to ensure a dedicated team of developers working on your project. Nextbrain is the leading software development company having experienced machine learning developers with several years of expertise in creating efficient ML-enabled applications.

At Nextbrain, we help our clients replenish their digital scenario as well as build premium connected systems with our advisory and consulting practice focused on generating greater value from their technology investments. Having a global team of professionals and technologists driving real business results for our clients, we assist you in beginning the journey toward unleashing the true potential of Machine learning in a more focused way. Get in touch with our professionals to know more about business growth combined with advanced technologies.