- 5 min read

- Jul 4, 2024

- 0

In the recent industrial landscape modern safety protocols are of primordial importance. Automotive industries are dynamic and need strict adherence and safety procedures. With the increase in the complexity of safety regulations, the need for automated solutions has begun. Workplace safety enables workers to work without any worries. For automotive industries, workplace safety can be determined with Personal Protective Equipment(PPE). It minimizes exposure to workplace hazards and injuries. However, it is important to enforce PPE compliance among workers.

Understanding the importance of PPE in workplace safety

As we delve deep into the importance of computer vision AI in the manufacturing industry, we need to comprehend why PPE is important in the industry. The automotive parts manufacturing business is a risky industry comprising many perils as a result of the use of heavy machinery and powerful tools. This makes it important to ensure safety while workers are working. Here lies the importance of PPE. Wearing PPE can effectively reduce any risk of injury in the workplace. It can seamlessly protect workers from various hazards such as chemical splashes, physical injuries and electrical shocks. Having job and safety satisfaction enables workers to work freely with increased productivity.

Compliance with PPE regulations involves guidelines, and standard practices for selecting, using, maintaining and disposing of PPE. However, there are certain challenges which cannot be avoided.

What are the challenges involved in PPE compliance?

Selection & availability

Selecting the right PPE for workers is important. It can be challenging to find the availability of suitable PPE.

Comfort & fit

In terms of comfort and fittings, several PPE items like gloves, safety glasses and masks can be uncomfortable to wear for extended periods.

Inadequate training & awareness

Proper wearing of safety gear is relevant and improper fitting can result in limiting its effectiveness over the course of time.

Enforcement & monitoring challenges

Manual monitoring can sometimes lead to flaws. Lack of proper supervision and accountability measures can result in compliance glitches.

This is where lies the importance of computer vision AI. Here’s an overview of the application of PPE detection systems using computer vision in the automotive parts manufacturing industry.

Computer vision & its influence on PPE compliance

AI technology helps devices to interpret, analyze and understand visual data from the real world. It can be harnessed to train data models for identifying patterns and objects from images and videos. Helping in improved decision-making, AI technology offers real-time monitoring of video streams and analyzes them to generate actionable insights. It has become increasingly important to automate tasks that were previously performed manually. It has numerous applications across industries comprising retail, healthcare and manufacturing. From analyzing video footage to real-time PPE detection, our AI computer vision services in PPE compliance can be used to detect PPE compliance among workers in any hazardous facility.

How AI have enhanced PPE compliances in automotive industries

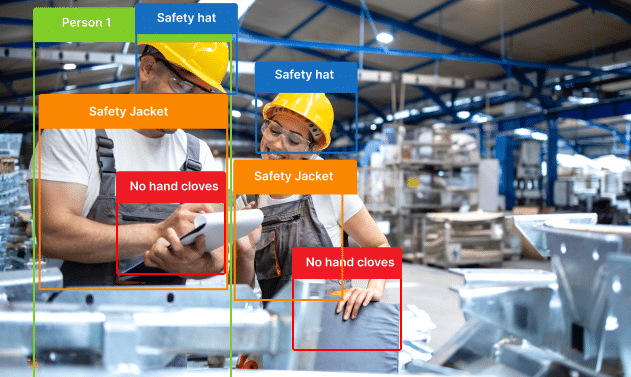

Computer vision systems use deep learning algorithms to detect the presence of PPE and monitor compliance with safety protocols. The system can trigger an alarm whenever it observes workers entering the working zone without PPE. Here’s an overview of the pivotal role AI plays in PPE compliance.

Data-driven insights

AI technology generates valuable data on PPE compliance patterns and trends. It analyzes the data so that organizations can recognize areas for improvement, embrace training opportunities and execute targeted interventions for improving their safety performance.

Effective resource allocation

Artificial intelligence technology is capable of allocating resources depending on real-time data on PPE usage. It prevents inessential spending and ensures PPE compliance across premises.

Remote monitoring

In a rigorous environment where direct supervision is limited, computer vision systems can remotely monitor PPE compliance. It enables security personnel to supervise different locations and leverage actionable insights.

Rapid response to non-compliance

Within the parts manufacturing factory premises, on detection of PPE violations, computer vision technology immediately triggers alarms and notifies the same. These instant alerts seek responses from security personnel to supervise different locations.

Higher accuracy

With the AI PPE compliance detection system, it can detect and identify different ranges of safety gear analyzing exact computer vision algorithms. This enables workers to wear the right equipment. It significantly diminishes the risk of non-compliance due to manual error.

Increased accountability

Computer vision systems help in promoting accountability among employees and supervisors. It can seamlessly monitor workers wearing PPEs. This enables active accountability among employees to follow safety rules in a manufacturing infrastructure.

Compliance documentation

Manual monitoring can have flaws and overlooked PPE compliances. However, computer vision systems automatically generate PPE compliance documentation and reports effectively helping in regulatory compliance.

Privacy concerns

Computer vision AI technology helps in processing images and video streams of people. It ensures data privacy and generates actionable insights on detecting violations of PPE compliance.

Final thought

Gone are those days of manual monitoring. Human errors are unavoidable. Here comes the intervention of the AI PPE detection system. PPE compliance powered by computer vision helps in automating real-time monitoring of safety gear. This enforces PPE compliance leading to improved workplace safety, reduced expenses and enhanced efficiency. Considering computer vision benefits across different industries, its challenges and limitations can be overlooked. Looking out for safety and compliance enforcement with computer vision artificial intelligence technology? Then we have got you covered. Nextbrain is the leading AI development company creating computer vision platforms for different industries.

In search of a suitable solution for your business? Get in touch with our professionals and learn more about computer vision AI.